|

Piave

Mill Co. (1918-1920)

Virgin

Pine Lumber Co. (1920-1933)

|

Standard gauge, 56-lb rail

Headquarters: New Orleans, LA

Mill Location: Piave, MS (Greene County)

Mill Capacity: 250,000 ft/day

Years of Operation: 1918-1933

Miles Operated: 14 miles in 1926

Locomotives Owned: 6?

|

Equipment:

1 McGiffert log loader, 1 Clyde 4-line skidder.

|

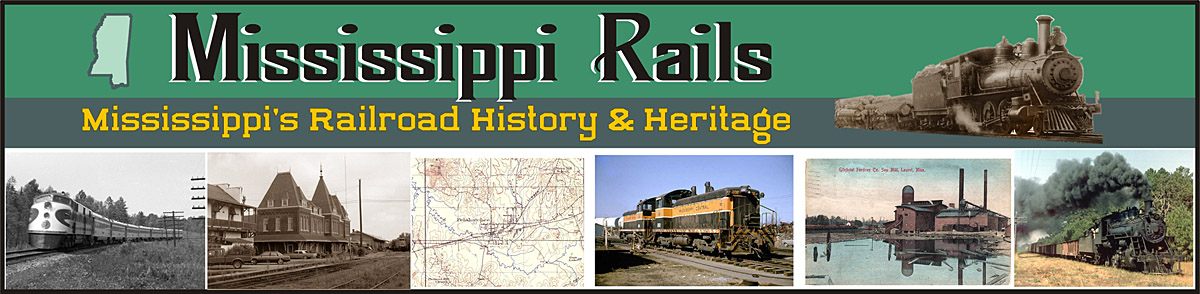

Click Map for Larger Version |

|

History

by Gil Hoffman and Tony Howe:

The

Piave Mill Company was incorporated for 50 years on August 17, 1918,

at Gulfport, Harrison County, by Henry Piaggio, W. B. Jordan and F. H.

Dickman, all of Gulfport, with capital stock of $250,000. It was a

subsidiary of the International Shipbuilding Company. Officers of the

company were P. G. Gurge-Salice, vice president, and C. Kahles, treasurer.

In October 1918, the company was operating sawmills near Ellisville, Jones

County, which cut ship material for the parent company.

On

October 7, 1918, the company contracted with John W. Blodgett, of Grand

Rapids, Michigan, for a block of his timber in Greene County. In October

1919, to cut this timber, a sawmill with a daily cutting capacity of 60,000

feet per day began operation at Piave, Greene County, on the Gulf, Mobile

& Northern Blodgett branch.

On

February 2, 1920, the sawmill (known as "sawmill No. 5"), all

lumber on hand, and the block of Blodgett timber under contract were sold to

the L. N. Dantzler Lumber Company. The operation was reorganized as

the Virgin Pine Lumber Company.

On

February 2, 1920, the L. N. Dantzler Lumber Company purchased the

sawmill plant and interest in the Blodgett timber of the Piave Mill

Company, at Piave, Greene County. To operate this property the Virgin

Pine Lumber Company was organized at New Orleans, Louisiana in May 1920

with $750,000 in capital stock. Officers of the company were J. L. Dantzler,

president; J. L. Hofstra, vice president, and E. P. Dumont, secretary and

treasurer. The mill at that time had a cutting capacity of 60,000 feet per

day. M. M. McInnis was general manager.

In

April 1923, the operation was leased with option to buy to Crosby and

Rowlands of Picayune, MS In the spring of 1924 a new double band mill

with a cutting capacity of 250,000 feet per day was built at Piave. L. O.

Crosby was general manager.

The

Piave mill cut out in November 1933.

|

The

Virgin Pine Lumber Co. Story

Or...

Where in the world is Piave, Mississippi?

By Tony

Howe

The South Mississippi town of Piave, in northern Greene County,

was home to one of the many large sawmills that were once located in

this state. During its existence, from 1917 until 1933, the sawmill at

Piave was the largest industry in northern Greene County, and provided

much traffic for Gulf, Mobile & Northern’s Blodgett Branch.

During the 1880's, facing a dwindling timber supply, many

Northern lumbermen invested in timberlands in the South. One of the

largest purchasers of Mississippi timberland was Delos A. Blodgett, from

Grand Rapids, Michigan. After two years of logging, Blodgett entered the

logging business for himself in Michigan in 1850, and invested profits

from his business in timberlands. In 1885, he began purchasing

Mississippi timberland from both the state and Federal government. By

1906 he reportedly owned 721,000 acres spread all over South

Mississippi. Most of this land was in Wayne, Greene, Jones, Perry,

Marion, Lamar, George, Jackson, Jeff Davis, and Pearl River counties.

Much of this land remained in the Blodgett family into the teens, and

was juggled back and forth between different members of the family,

including Edward Lowe, Minnie C. Blodgett, Daisy Peck Blodgett, and John

W. Blodgett. The Blodgetts, through the Blodgett Company, Limited,

also invested in timberlands in other parts of the country,

including Louisiana, South Carolina, Oregon, and California. Upon the

death of Delos Blodgett on Nov. 1, 1908, his son, John W. Blodgett, took

over as head of the Blodgett Co., Ltd. The Blodgett’s timberland in

Greene County covered much of the north half of the county, including

the area around Piave, and stretched well into Wayne County. This tract

remained untouched well into the late teens.

Several efforts were made to open up the tremendous Blodgett

timberlands in Greene, Perry, and Wayne Counties. Small tracts of the

Blodgett timber were sold to various mills that were operating along the

New Orleans, Mobile & Chicago RR, later the Gulf Mobile &

Northern RR, such as J.M. Griffin Lbr. Co. at Nomac, J.M. Hemphill at

Rhodes, Bentley & Emery at Ovett, Canal Lbr. Co. at Benmore, Wausau

Southern Lbr. at Laurel, and Richton Lbr. Co. at Richton. Other tracts

were sold to the Robinson Land & Lbr. at Chicora and the Bear Creek

Mill Co. at Leakesville. These companies extended their logging

railroads into these tracts, but large tracts of the Blodgett timber

remained untouched throughout the teens. The Alabama & Mississippi

Railroad, which ran from Vinegar Bend, Ala. to Leakesville, Miss., and

southward to Pascagoula, on the Gulf of Mexico, attempted to extend its

line from Leakesville to Laurel in 1915. The A&M was owned by the

Turner family, who owned the large Vinegar Bend Lumber Co. at Vinegar

Bend. They planned to use the Bear Creek Mill Company logging railroad,

which ran from Leakesville northwesterly to the community of Jonathan.

The A&M would build a new railroad from Jonathan, through the middle

of the Blodgett timberlands, to southwestern Wayne County, where they

would connect with the logging railroad of the Wausau Southern Lumber

Co., which ran all the way to their mill on the south side of Laurel.

The A&M hoped to acquire much lumber traffic from the large mills at

Laurel to deliver to the port at Pascagoula for export. As this would

siphon much traffic from the Gulf, Mobile & Northern RR, they were

very much against this. In an effort to prevent the construction of the

A&M line to Laurel, and to open up the remainder of the Blodgett

timberlands, the GM&N began construction of what became known as the

Blodgett Branch in 1917. The line was initially planned to run from

Richton to Waynesboro, but the junction with the GM&N mainline was

soon moved to a point near McLain, Miss. The line crossed the Leaf River

at McLain, and ran northeast and then northward through the middle of

the Blodgett timberlands, into the middle of Wayne County. Although

unclear today, John W. Blodgett probably cooperated in every way with

the GM&N, and probably promoted its construction. Having a railroad

through the timberlands meant that buyers for the land would be easy to

find. The line was completed to Wells, 21.6 miles from McLain, by

February 1919. By September 1919, the line was completed to Piave, 24.2

miles from McLain, and beyond to Muse, at Milepost 28.05 just north of

the Wayne County line by the following year. Although the line was

graded another 4 miles into Wayne County, it is unclear whether track

was ever laid on that segment. The Blodgett timber along that segment of

the line was sold to the Robinson Land & Lumber Co. and hauled to

their mill at Chicora by logging railroad.

On October 7, 1918, John. W. Blodgett signed a contract to sell a

block of his timber to the Piave Mill Company. This timber was located

north, northwest, and west from the present-day community of Piave, in

northern Greene County, and consisted of 4564 acres of land, or about 8

square miles. The Piave Mill Company had been incorporated at Gulfport

only two months before, on August 17, 1918, by Henry Piaggio, W.B.

Jordan, and F.H. Dickman, with a capital stock of $250,000. The name

Piave came from Piaggio, and most likely came from the river in Italy by

that name. Piaggio, a native of Italy, was president of the

International Shipbuilding Company, which had a shipyard at Orange,

Texas, and had built a large shipyard at Pascagoula, Miss. in mid-1917.

Piaggio had reportedly been in the timber business, exporting large

amounts of lumber to Italy. International Shipbuilding received a

contract with the Italian government to build several ships for the war

effort then getting under way, and built the shipyards to build these

wooden ships. The Piave Mill Company was incorporated as a subsidiary of

International Shipbuilding to supply the shipyard at Pascagoula with

lumber for ship construction. In late 1917, Henry Piaggio purchased a

tract of timber in Jones County southeast of Crotts, on the GM&N

between Ovett and Laurel. A sawmill was operated on the south side of

Crotts to cut this timber. In early 1918, Piaggio also purchased timber

west of the GM&N near Ellisville Junction, and built a mill near the

site of the J.H. Bostick mill at Ellisville Junction. These mills were

also operated to supply the shipyard at Pascagoula.

To cut the Blodgett timber at Piave, a circular sawmill was built

with a daily capacity of 60,000 board feet. Construction of this mill

began by June 30, with the mill finally starting operation in October of

1919. The mill was under the management of Thomas Carruth, a lumberman

from Lamar County. Carruth had operated sawmills at Rosine, in Forrest

County, and at Coral, near Sumrall in Lamar County. Like Piaggio’s

other mills, this mill only cut timber for use in the construction of

the ships at the Pascagoula shipyard. A 24-ton Shay was purchased from a

lumber company in Minnesota, most likely for use on the short logging

railroad running northwest from Piave. For use in the woods, a 4-line

skidder (C.N. 320) and a McGiffert log loader (C.N. 1235) were purchased

from the Clyde Iron Works, of Duluth, Minn., and delivered to Piave in

late August 1919.

The sawmill at Piave barely got into full operation when the war

in Europe was over. The shipyard at Pascagoula completed at least five

ships. With no further orders of ships after the war, the shipyard at

Pascagoula was closed. With no further need for a sawmill, Piaggio sold

the Piave Mill Co. mill at Piave, known as “Sawmill Number 5" to

the L.N. Dantzler Lumber Company, of Moss Point, on February 2, 1920.

This deal included the sawmill, logging railroad, and the block of

Blodgett timber that had not been totally paid for. Dantzler reorganized

the company as the Virgin Pine Lumber Company. The new company was

incorporated in May 1920 in New Orleans with $750,000 in capital stock.

Officers of the company were J. L. Dantzler, president; J. L. Hofstra,

vice president, and E. P. Dumont, secretary and treasurer. The mill at

that time had a cutting capacity of 60,000 feet per day. M. M. McInnis

became general manager.

Under Dantzler ownership, at least two locomotives were purchased

for use at Piave. A 50-ton, 2 truck Shay was purchased in February 1920

from the Oklahoma Portland Cement Co. of Ada, Oklahoma. This engine was

numbered 15 by Virgin Pine. Another Shay was purchased by March 1920

from the White Lumber Company of Greenville, Tennessee. This locomotive,

numbered 3 by Virgin Pine, was a 42-ton, 2 truck Shay.

Another change in ownership came in April 1923 when the operation

was leased with option to buy to L.O. Crosby and Lamont Rowlands of

Picayune, MS. The name Virgin Pine Lumber Company was retained by the

new company. Crosby and Rowlands had operated the Rosa Lbr. Co. and the

Goodyear Yellow Pine Company at Picayune since 1917. In 1921, Crosby and

Rowlands purchased the J.M. Griffin Lbr. Co. at Blodgett, Miss., on the

GM&N 3 miles south of Ovett. Most notably, the timber holdings of

the J.M. Griffin mill were located in southwestern Wayne County, just

north of Piave. These timberlands were purchased from Minnie C. Blodgett.

More importantly, Crosby and Rowlands had already obtained leases on the

largest remaining tract of Blodgett timber sometime before April 1923.

This tract of timber was located in northern Greene County, immediately

east of Piave, and included nearly a whole township (36 square miles),

and in scattered blocks in southern Wayne County. Crosby and Rowlands

acquired the mill at Piave to cut this timber, which was possibly bought

to supply the mill at Blodgett.

The small circular sawmill purchased from the Dantzler company

was soon deemed too small to cut the large timber holdings owned by the

Crosby interests. Crosby had initially planned to tear down the old mill

and replace it with one much larger on the same site. On October 5,

1923, a fire saved Crosby the trouble of tearing down the old mill.

After clearing the debris from the fire, work soon started on a new mill

under the direction of Harry Mitchell. Southern Lumberman magazine of

March 1, 1924, describes the new mill:

“Piave, Miss.,

Feb. 25 -- The mill will be

equipped with two bands and a horizontal resaw and designed to saw

timbers up to 70 feet in length. When

completed, this mill will be one of the most modern in existence.

All machines will be motor driven, and new types of electrical

controls have been incorporated so that the various drives will be able

to meet any demand that can possibly be placed on them.

Several new types of control apparatus were developed especially

for this plant, and operation of various units worked out to a state of

refinement never heretofore attempted.

The mill was designed by L. L. Hart, of the Allis-Chalmers

Mfg. Co., Milwaukee, Wisc., and the entire equipment including power

house, motors, reducers and sawmill machinery, with the exception of two

bands is being supplied by them. The

power house is worthy of special mention, the Allis-Chalmers steam

turbine, generator, condensers, switchboards, motor generator set, motor

driven air compressor, boiler feed and circulating pumps, etc., are all

conforming to the latest standards and best engineering practice and are

combined into a well balanced power producing unit that can only be

approximated when the different units are supplied by different

manufacturers.

Especially interesting features include a seven-block

carriage with motor driven set-works on the long side.

On this side also are placed two niggers so that turning long

logs will be very much simplified.

The edgers are driven by direct connected motors mounted on

structural steel sub-bases. Edger

feed rolls are driven by separate motors and are reversible and variable

speed. Trimmers will be of

the air lift type and fitted with Allis-Chalmers improved air valves.

Allis-Chalmers special sawmill type motor reduction

gears are being used throughout on all low speed drives.

New electrical controls which add materially to operating

efficiency are being used in connection with them on transfers and other

intermittent drives.

The arrangements for handling material after it leaves

the mill proper have been carefully worked out in conjunction with the

mill itself; the large general plan drawn to 1/4" scale, is

eighteen feet long, although the mill itself is 70 feet shorter than the

conventional design, due to close utilization of space and slightly

different arrangement of machines resulting in a considerable saving in

mill cost. No trouble or

expense has been spared to make this the most modern and efficient

sawmill ever designed, both regarding the mill itself and sorters,

transfers, etc., outside.

The Virgin Pine Lumber Co., and associated interests

own one of the finest remaining stands of Southern pine, having

700,000,000 feet at Piave, and other tracts in favorable locations

nearby, insuring them many years of uninterrupted operation.”

Soon after the new mill was placed in operation, Crosby

transferred several Shay locomotives from the operation at Blodgett.

These included 36-ton 2 truck Number 4, 65-ton 3-truck Number 11, and

50-ton 2-truck Number 2, which was renumbered to 1 at Piave. A 50-ton

Baldwin 2-6-0 was also purchased secondhand sometime before February

1926. The logging railroad was gradually extended into the timber

holdings of Virgin Pine Lbr. Co. east of Piave. On April 29, 1926,

Virgin Pine also purchased from the GM&N the portion of the Blodgett

branch running north from Piave into Wayne County. Virgin Pine utilized

this track to reach timber holdings in southern Wayne County, and built

logging spurs both eastward and westward off of this line. By June 1926,

logging crews were also cutting timber in the northeastern area of the

timber holdings in Greene County.

One of the head sawyers at the Piave mill was Fonzie Lee,

originally from Mobile County, Alabama. Lee began his sawmilling career

at Piave in 1924, when he started as a relief sawyer. He soon

transferred to the mill at Blodgett, where he also worked as a relief

sawyer. The C&R Lumber Company mill at Blodgett was a single band

mill, with a right-hand band saw. In 1926, Lee left Blodgett to learn

how to saw on the left-hand rig at Piave, where the mill had two 9 foot

band saws. Lee started out as a relief sawyer at Piave, but worked up to

become the regular sawyer. After becoming the regular sawyer, Lee worked

mostly on the long side, which was set up to cut timbers up to 70 feet

long. The long side had a twin engine that pulled a cable that pulled

the carriage back and forth. The long timbers, which were being cut

mostly for export, were stored in a special pond next to the mill until

they had enough to ship out. When asked about his hours of work, Lee

responded:

“When

I first went there we worked 6 ten hour days a week. When I first began

sawing they were paying 90 cents an hour, $54 a week. When the

Depression came on they began cutting wages so fast I didn’t hardly

know what I was making for a while. It wound up during the Depression I

was sawing for 49 cents an hour, 60 hours a week. When they declared the

NRA they cut hours down to 40 a week and they raised my wages to 65

cents an hour. I went from about $29 a week to $26 a week. I began to

think we were going in the wrong direction!”

When Fonzie

Lee started working at Piave in 1926, the plant superintendent was a Mr.

Martin. After Mr. Martin left, his replacement was Jim Ferguson, who

came from Blodgett. Ferguson remained plant superintendent until the

mill closed in 1933. In 1926, the mill foreman was Jim Hutchins. The

last saw filer for the Virgin Pine Lumber Company was S.N. Green, who

stayed until the mill cut out, and like many employees at Piave,

transferred to Crosby. The chief engineer at Piave was Curtis Mitchell,

who also transferred to Crosby and later became plant superintendent

there.

During the early 1930's, logging crews were working in the area

southeast of Piave, near Turkey Fork and Camp Creek. According to Fonzie

Lee, the company didn’t have logging camps, as the people who worked

in the woods lived in Piave and rode the train to the woods. According

to Henry Watson, who moved to Piave around 1930, the company operated 4

log trains into the mill daily, each having about twenty cars. The

locomotives were maintained in the machine shop that was located just

north of the mill.

When the mill was in operation, the town of Piave thrived. The

town’s business district was centered around the GM&N depot. There

was a mercantile store operated by A.B. Miles. Another store was operated

by Sam Swinnel, and a café was located between the two stores. Audrey

Hollingsworth also operated a store, and lived upstairs above the store.

Also located downtown were barber shops, cafes, a dentist office, an ice

plant, a cotton gin, a Baptist church, a meat market, a hotel, and several

homes. The Piave High School was located west of downtown.

The railroad also had several section houses, a turntable, and a

water tank. Near the sawmill, the lumber company built a large company

store, which at one time was run by John Minter. Near the company store

was the post office, a barber shop, a hotel, and a Methodist church. Above

the company store, the road split into two streets, known as Long Street

and Short Street. Along both of these roads, the lumber company built many

mill houses, mostly small frame houses, for the mill employees. According

to Watson, the larger nice homes for the mill officials were located along

Long Street. North of the log pond were located the quarters for the black

workers. Just north of the mill, the lumber company also operated a

turpentine still.

By the early 1930's the company was facing a limited timber supply.

In November 1933, the sawmill at Piave was finally closed. Several of the

employees transferred to Crosby, Mississippi, in the southwestern part of

the state, where the Crosby Lumber & Manufacturing Company was

rebuilding the sawmill they had just purchased from the Foster Creek

Lumber & Manufacturing Company in 1934. Shay locomotives number 1 and

11 were transferred to Crosby, as well. The oldest Shay, number 4, was

scrapped at Piave. Much of the machinery from the mill at Piave was

removed and brought to Crosby. The band mills were shipped to Crosby and

used for parts in the mill there. The electric motors were also brought to

Crosby, as the mill there was an all electric mill, too. A 6 foot

horizontal band resaw was shipped from Piave and installed in the mill at

Crosby.

After the mill closed, most of the people quickly moved away. Many

of the stores closed or moved away, and Piave became a ghost town almost

overnight. Most of the homes in Piave were torn down and the lumber sold

off. According to Henry Watson, one could buy at house for $10 or $15

after the mill closed. The GM&N Blodgett Branch struggled on another

year or so after the mill closed. After many of the sawmills closed, there

was very little traffic on the branch, and it was abandoned in 1935. The

only reminder of the large sawmill that once stood at Piave are the large

concrete walls of the fuel house and boiler house standing alone in the

thick woods near the mill pond.

|

The

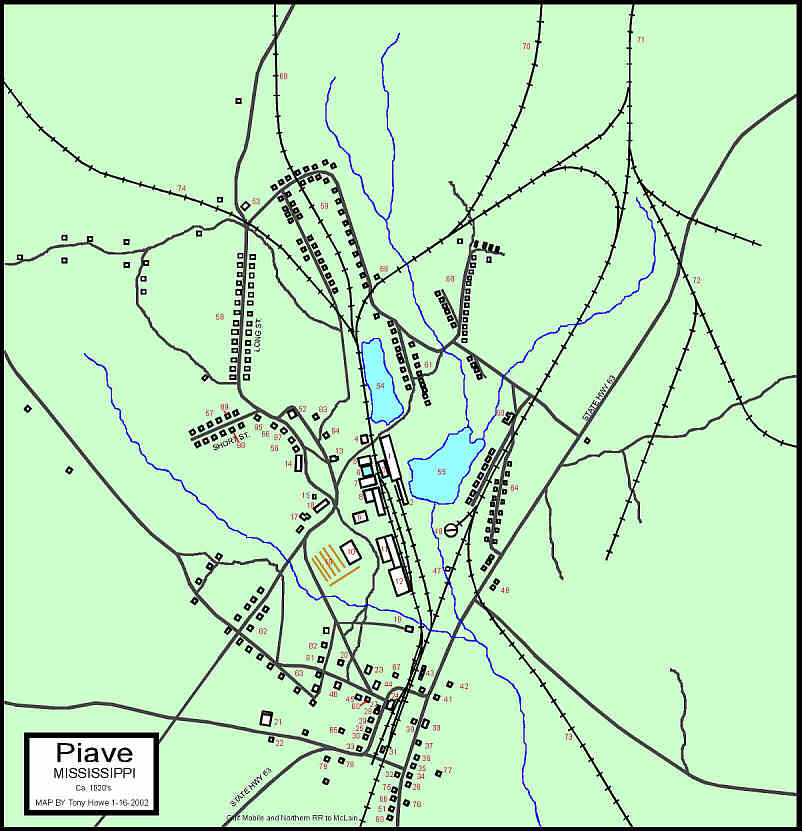

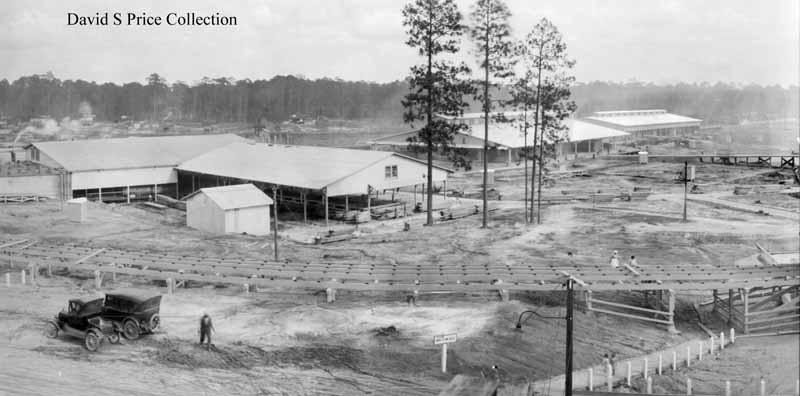

Virgin Pine Lumber Co. mill at Piave in 1925. This overall view looks to

the east. |

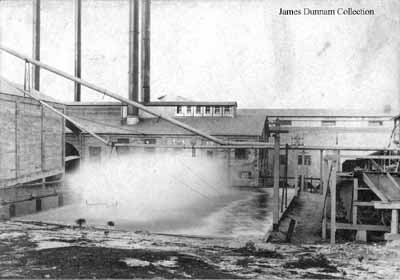

The Virgin Pine mill from the mill pond looking southeast. |

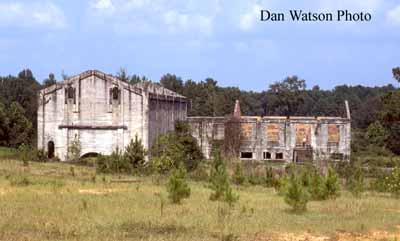

The concrete walls of the shavings vault and boiler room remain today.

The shavings vault is the far left building in the 1925 photo above. |

The right section of the 1925 panoramic photo show the lumber sheds and

planing mill, and looks to the southeast. |

The cooling pond and boiler room. This 1920's photo is about the same

angle as the 1970's view above. |

The

remaining structures at Piave in 2021. Mark Merritt Photo |

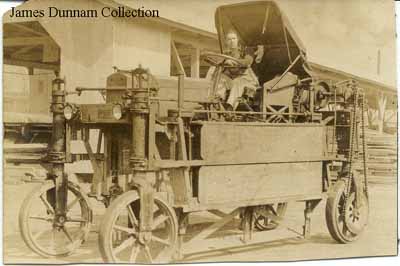

Straddle-type electric lumber carrier at Piave. |

Piave 2021 Mark Merritt Photo |

Piave 2021 Mark Merritt Photo |

Piave 2021 Mark Merritt Photo |

Piave 2021 Mark Merritt Photo |

|

Piave 2021 Mark Merritt Photo |

| ROSTER by Gil Hoffman:

|

Road

No.

|

Type

|

Builder

|

C.N.

|

Date

|

Cyls.

|

Dri.

Dia.

|

Engine

Wt.

|

Previous

Ownership

|

Disposition

|

|

1

|

50-2

Shay

|

Lima

|

3104

|

5/1920

|

3-11x12

|

32

|

100000

|

J.

M. Griffin #2, Blodgett, MS

C.

& R. Lumber Co. #2, Blodgett, MS,

on

7/1/1921.

Virgin Pine Lumber Co. #1, on ?

|

Crosby

Lumber & Manufacturing Co. #1, Crosby, MS, ca. 1934.

Scrapped 1954.

|

|

3

|

42-2

Shay

|

Lima

|

2443

|

5/1911

|

3-10x12

|

29½

|

84000

|

Greenville

& Nolachuckey Ry. #1, Greenville, TN (John Heilman Lumber Co.)

White

Lumber Co. #1, Greenville, TN

Virgin Pine Lumber Co. #3, by 3/1920.

|

Last parts order, 8/28/1930.

|

|

4

|

36-2

Shay

|

Lima

|

2096

|

6/1908

|

3-10x10

|

28

|

72000

|

Lacey

Lumber Co. #4, Carriere, MS

Rosa

Lumber Co. #4, Picayune, MS,

in

1917.

Goodyear

Yellow Pine Co. #4, Picayune, MS

C.

& R. Lumber Co. #4, Blodgett, MS,

in

6/1922.

Virgin Pine Lumber Co. #4, in 9/1924.

|

Scrapped 1933.

|

|

11

|

60-3

Shay

|

Lima

|

3197

|

12/1922

|

3-11x12

|

32

|

133000

|

C.

& R. Lumber Co. #11, Blodgett, MS

Virgin Pine Lumber Co. #11, by

11/1929.

|

Crosby

Lumber & Manufacturing Co. #11, Crosby, MS, in 9/1937.

Retired

1958.

City

of Natchez, MS, on 4/30/1965

(for display).

|

|

15

|

50-2

Shay

|

Lima

|

2977

|

5/1918

|

3-11x12

|

32

|

100000

|

Oklahoma

Portland Cement Co. #2, Ada, OK

Virgin Pine Lumber Co. #15, in

2/1920.

|

C.

& R. Lumber Co. #15, Blodgett, MS,

by

7/1926.

Goodyear

Yellow Pine Co. #15, Picayune, MS, by 4/1931.

Crosby

Lumber & Manufacturing Co. #15, Crosby, MS, on 8/14/1944.

Re.

#1.

Pascagoula

Veneer Co. #1, Crosby, MS,

in

1957.

Thomas

Lawson, Jr., Birmingham, AL,

Eureka

Springs & North Arkansas Ry. #8, Eureka Springs, AR, in 1983.

Lowville

& Beaver River Ry. #8, Lowville, NY, in 1989.

Railway Historical Society of

Northern New York, Croghan, NY

|

|

101

|

2-6-0

|

Baldwin

|

|

|

|

|

100000

|

Unknown.

Virgin Pine Lumber Co. #101, by

2/1926.

|

|

|

HOME

ABOUT US

LINKS

For more information contact

Tony Howe at tonyhowe76@yahoo.com

or David S. Price at dsprice46@bellsouth.net

|