Foster Creek Lumber & Manufacturing Co.

Crosby Lumber & Manufacturing Co.

|

Standard Gauge, lb. rail Headquarters: Stephenson, MS later called Crosby, MS after 1935 Officers (): Years of Operation: 1916-1963 Miles Operated:

Locomotives Owned: |

Equipment

|

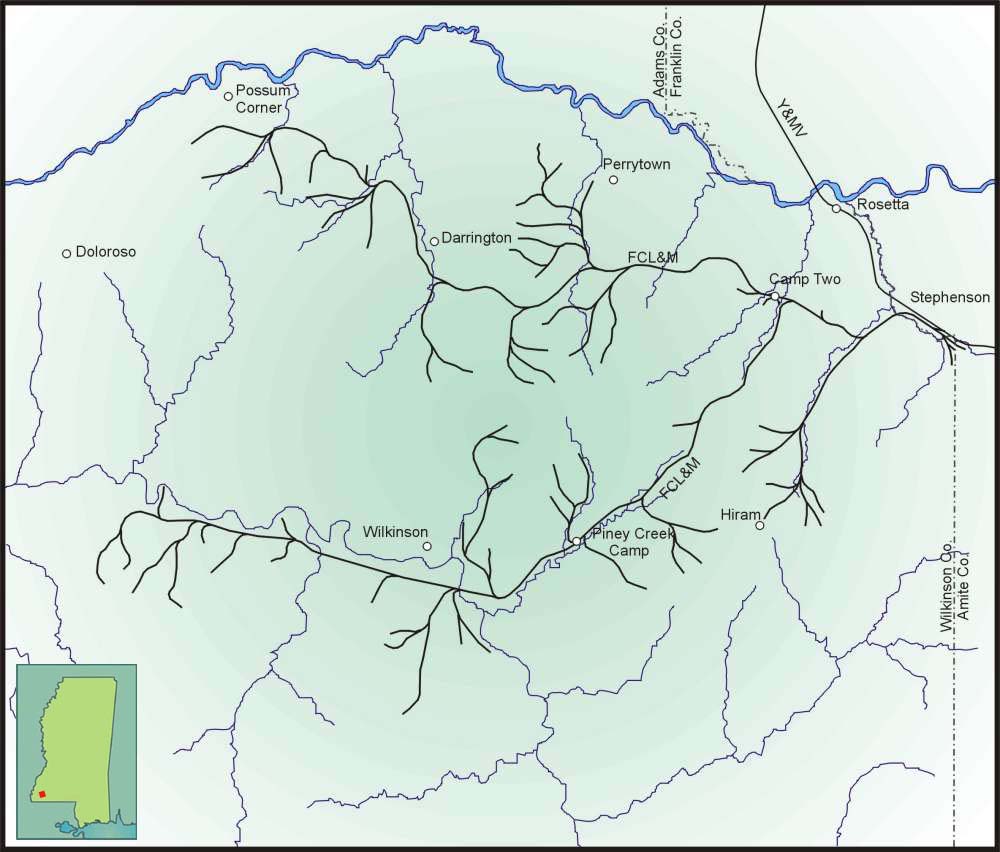

Click Map for Larger Version |

|

H.G.

Butler Foster

Creek Lumber Co.

One of the largest sawmills in southwestern Mississippi was

once located on the Yazoo & Mississippi Valley Railroad where it

crossed the Wilkinson-Amite County line. Like most of South

Mississippi, this part of the state was once covered in great expanses

of forest, consisting of mixed longleaf yellow pine, shortleaf pine,

and various species of hardwoods. The small town of Dayton grew up

after the completion of the railroad in 1884. H. G. Butler moved his

small sawmill from Knoxville, Mississippi, to a point about a mile

southeast of Dayton in 1900, and built a 36-inch gauge logging

railroad to supply this mill with logs. The area around the mill was

soon known as Butler’s Spur. In July 1903, the Butler mill,

timberland, and railroad was sold to D. H. Donaldson, who formed the

Foster Creek Lumber Company to operate the property. The sawmill at

Dayton operated until

late 1908, when it was finally shut down and the equipment sold off. Foster

Creek Lumber and Manufacturing Company

Even though the mill shut down, the Foster Creek Lumber Company

continued to exist as a timber buying company. After several years of

buying timber, the Foster Creek Lumber Company had accumulated about

52,000 acres of land in northern Wilkinson County and northwestern

Amite County. In early 1916, two brothers from Michigan heard about

the availability of this timber. George L. and Fred M. Stephenson were

involved in building several sawmills in Mississippi and Louisiana,

and traveled to Dayton

and met with T.B. McCurley, land agent of the old Foster Creek Lumber

Company, who took them out to look over the timber. The Stephenson’s

must have liked what they had seen. They went back north and

incorporated the Foster Creek Lumber and Manufacturing Company to take

over the holdings of the Foster Creek Lumber Company. The new company

was incorporated in the state of Wisconsin with a capital stock of

$1,500,000. Along with the Stephenson’s, other incorporators

included Edward J. Young and A.E. Proudfit of Madison, Wisc. On April

1, 1916, Foster Creek Lumber and Manufacturing Company purchased the

entire holdings of the Foster Creek Lumber Company. The new owners

quickly set out to build a new sawmill near the site of the old mill.

The site selected for the new mill was just south of the Y&MV,

right on the county line. The log pond was actually located in Amite

County, while the mill was to be built in Wilkinson County. Work on

clearing the mill site was completed by July 1916. The contract for

the construction of the sawmill was awarded to the Prescott Company of

Menominee, Michigan, by August 1916. Plans for the new double band

milled called for the entire mill to be electrically driven. This was

not a totally unique idea, as the Sumter Lumber Company at Electric

Mills, Mississippi, already had a large mill powered by electricity

that was built in 1911. Details of the new mill were released in the

American Lumberman: “The sawmill will be one of the largest in the South, embodying all the latest improvements in machinery, and will be electrically driven throughout, each machine being run by a separate motor. The

sawmill proper will be 70 by 248 feet with a timber dock extending 192

feet from the mill. A double drop sorter and a separate green lumber

sorter equipped with all of the latest time- and labor-saving devices

will be installed. The

equipment of the sawmill will consist of two 9-foot Prescott band

mills, an 8-foot Prescott vertical resaw, one five-block 44-inch

carriage and one three-block 44-inch carriage, with steam sets and

steam receders; two 72x8-inch edgers connected directly to motors;

slasher and air operated trimmer and a complete lath mill. The log

deck will be equipped with the latest improved kickers, stops, and

niggers of the heaviest construction.

The power house will be of brick and steel construction, 80 x

92 feet, as will be the fuel house, 30 x 72 feet. The power plant will

consist of eight 84 x 18 high pressure boilers with dutch oven fronts

and steel case marine settings. The power will be furnished by two 600

kilowatt and one 300 kilowatt General Electric high pressure

condensing turbines, one General Electric 10 kilowatt turbine driven

exciter, one General Electric 25 kilowatt motor driven exciter, one

Ingersoll-Rand barometric condenser with capacity for all the

turbines. A motor driven pump will take water from a creek 1,000 feet

from the mill. The condenser hot well will be provided with an

overflow into the mill pond. Also boiled feed water will be taken from

the hot well, allowing one pump to supply the entire plant.

Thirty-four motors will be utilized in the sawmill and ten in the

planning mill. The entire installation will be wired in conduit in the

latest improved manner. Edward

D. McKellar, representing the General Electric Company at New Orleans,

designed the power plant and the electrical installation. The planning

mill machinery will be furnished by P. B. Yates Machine Company,

Beloit, Wis., and the dry kilns by the L. Moore Dry Kiln Company,

Jacksonville, Fla.”

As construction on the mill

started, work was also underway on the new town near the mill. The

town was laid out parallel to the Y&MV Railroad, north of the

tracks. What was once the fields of T.B. McCurley was transformed into

a neat little town complete with modern homes and paved sidewalks. A

small commissary and post office was built near the railroad. Much of

the old town of Dayton was moved to the new town, which became known

as Stephenson. In October 1916, a charter was filed

for the incorporation of the new town of Stephenson. As January

1917 approached, work on the mill continued, and equipment for the

logging railroad began to arrive. A secondhand Pittsburgh-built 2-8-0

was purchased from Birmingham Rail and Locomotive Co. in December

1916. Weighing about 60 tons, this locomotive was numbered 6 by Foster

Creek. A 32-ton 2-truck Heisler locomotive was also purchased from a

lumber company in South Carolina in early 1917. This locomotive was

numbered 1. A number of log cars and a Clyde 4-line skidder also

arrived on the property by 1917. In addition, a combination ditcher

and log loader was purchased from the American Hoist and Derrick Co.

The mill was finally finished by July 1917 and was started up. It had

a capacity of approximately 170,000 board feet of lumber per day and

employed over 600. Shortly

after the mill was up and running, the Stephenson’s sold their

interest in the company in 1918. They were mainly interested in

building sawmills, not in the operation. Edward J. Young then

became president of the Foster Creek Lumber & Manufacturing

Company. As the mill was being finished up, work started on building the standard gauge logging railroad from the sawmill to the timber holdings. The railroad was built from the sawmill northwestward parallel to the Y&MV mainline for about a mile, where it swung southward to follow Tar Creek. One of the first areas to be logged by the company was southwest of Stephenson near the headwaters of Tar Creek near Hiram. Heisler Number 1 handled the loader while Number 6 switched at the mill. At that time those were the only engines owned by Foster Creek. The track at that time was too rough for the rod engine to go out on. In the very early days of logging, Foster Creek was logging with mule and ox teams and Lindsey eight-wheel log wagons. In addition to pine, a lot of hardwood was logged near Hiram. The company built a small log camp on this early railroad near the company demonstration farm that lasted about a year. In 1919, the logging railroad was greatly expanded. To tap into the heart of the Foster Creek timber holdings, a new branch of the railroad was built westward from Stephenson. Before this could be done, however, a steep ridge had to be crossed. A deep cut was dug through this ridge that lessened the grade somewhat, but it still remained the steepest hill on the railroad. Just west of this hill, near Dry Creek, the first large logging camp of Foster Creek was built in 1919. This camp, called Camp Two, remained the main camp of the company until it shut down during the Great Depression. A new 47-ton 3-truck Heisler was purchased in 1918 and numbered 3. Another Heisler was also purchased new the following year. Weighing in at 75 tons, this locomotive was numbered 4. In 1920, another large Heisler was added to the roster. This engine, Number 2, was the largest owned by the company. This 3-truck Heisler weighed 85 tons. Also during 1920, a second skidder was added by the company to supplement the one already in operation. This skidder was different than the first one purchased by the company in that it was a 2-line skidder, where the first skidder was a 4-line machine. This second skidder, which was also purchased from the Clyde Iron Works of Duluth, Minnesota, was called a bob-tail skidder because it only had a boom on one end, where the 4-line skidder had two large booms, one on each end.

In 1922, when Frank Moore moved to Stephenson to become a

regular sawyer on the left-hand rig, the mill consisted of two 9-foot

band mills, a 42-inch gang saw, a horizontal resaw, and a lath mill.

The left-hand side was the short side, while the right-hand side was

the long side. The mill was cutting between 165,000 and 175,000 feet a

day, running 10 hours a day. Once in a while, the mill would run 11

hours a day by the late 1920’s. The mill was cutting both pine and

hardwood on the same saws.

Construction on the main logging camp of Foster Creek Lumber

and Manufacturing Company at Camp Two started in 1919. To maintain the

locomotives used on the logging spurs, the camp had a small machine

shop and servicing facilities. A sand house and coal bin was located

in the camp. The camp also had a commissary, a hotel, a school, and a

doctor’s office. The store, which was run by Quitman McLemore, had a

meat market in the back. The camp was divided into two sections, one

for whites and the other for blacks. In the black section of the camp

there was a large building known as the barrelhouse, where there was

drinking, dancing, and gambling. Most of the people who worked in the

woods lived in Camp Two, including the logging superintendent,

loggers, and train crews. The small camp houses were all built at

Stephenson and loaded on log cars and shipped to the camp on the

logging railroad. In

1918, Mr. Clarence Jenkins was given the job as timekeeper and payroll

man, according to him simply because nobody else wanted the job. He

worked in the office at Camp Two, and lived in two camp houses there.

He remembered most of the houses in the camp were about 12 or 13 feet

wide by 24 or 26 feet long, well-built, and ceiled inside, and drop

siding outside. Jenkins had one shack 12x24 feet and a smaller one, a

front porch, and a screened back porch. He built a platform and placed

a large tank on top of it, and ran a gutter from the eve of the house

that caught the water so that he would have running water in the

kitchen sink. The logging superintendent had two shacks about 12 by 24

feet, a front and back porch, and a water tank for running water. Most

houses in the camp didn’t have running water. The houses were heated

by wood stoves, and most of the cooking was also done on the wood

stoves. Jenkins remembered that they had to take a bath in a #3 wash

tub. Rent for the houses like the one Jenkins lived in was $7.00 per

month. Other shacks that were about 12 feet by 12 feet rented for

$1.50 per month. Most families would have two or three of these

shacks. The hotel at the camp served breakfast, fixed the men’s

lunches in brown paper bags, and had their supper ready when they got

in. When the camp was first built room and board in the hotel was 65

cents a day, which was raised to $1 a day by 1921. There were two beds

in each of the sleep shacks near the engine facilities in the camp.

Usually single men would stay in these sleep shacks, while most

families had their own shacks. To get supplies to the store, the

company had a boxcar that was used about once a week to haul supplies

from the store in Stephenson to the camp. In the early 1920’s a

water tank was built at Camp Two to supply water for the locomotives,

loaders, and skidders. Prior to this time, water was most likely taken

right out of the creek that ran near the servicing facilities. To

supply water to this tank, Mr. Braswell, the logging superintendent,

dammed up a hollow next to the railroad up on the hill east of the

camp. A pipe was run from the dam to the water tank to keep it filled. Between

1920 and 1926, Foster Creek Lumber and Manufacturing Company was

logging the area west of Camp Two, extending as far west as Possum

Corner. The logging railroad was gradually extended westward from Camp

Two. By 1922, crews were logging the area near Turkey and Beaver

Creeks. In 1923 and 1924, they were working further down Beaver Creek,

near the community of Perrytown. The main line was built to Darrington,

where it turned north and followed along the west side of the east

fork of Crooked Creek for about two miles. At this point it turned

west. Crews logged the area west of Crooked Creek in 1925 and 1926.

When the camp was built, the track between there and the

sawmill was upgraded so that the rod engine, Number 6, could run all

the way to the camp. Gravel ballast was used to shore up the track.

After the track was upgraded, Number 6 usually hauled the log trains

from the camp over the big hill to the mill. The Heislers were used to

switch the log spurs and were all kept at the camp. The crews would

usually leave the camp early in the morning, around 4 o’clock, and

head out to the woods. Each crew would load a certain number of logs.

That was a day’s work, and they would then bring them in to the

camp. Sometimes they wouldn’t get back until way after dark, maybe 8

or 9 o’clock. They would leave the skidders and loaders where they

quit working for the night. They had a night watchman that would take

care of each one. Number Six was based in town and usually made one

round trip out to the camp and back a day. If the mill got short of

logs, Number Six would make two round trips.

Foster Creek Lumber and Manufacturing Company wasn’t the only

mill owned by E. J. Young. He, along with other Foster Creek

stockholders, also owned mills in British Columbia, Alabama, and

Louisiana. They owned the Black River Lumber Company at Willetts,

Louisiana. They incorporated the Wisconsin-Alabama Lumber Company on

June 21, 1917, and built a large mill at Sylacauga, Alabama. On April

12, 1924, they also purchased the Arkansas-Alabama Lumber Company at

Wetumpka, Alabama.

After the Arkansas-Alabama Lumber Company mill at Wetumpka was

purchased, two Shay locomotives were transferred to Stephenson in May

1924. Arkansas-Alabama Number 3, a 45-ton two truck Shay, became

Foster Creek Number 5. The other locomotive, a 65-ton three truck

Shay, became Foster Creek Number 8. Foster Creek sold 47-ton Heisler

Number 3 around 1925 to the E. L. Bruce Lumber Company of Memphis.

This locomotive, which was usually used on the steel gang, was

replaced by Shay Number 5. 32-ton Heisler Number 1, which usually

switched the mill, was sold to Southern Iron & Equipment Co., a

used equipment dealer, sometime before March 1927. When the

Wisconsin-Alabama Lumber Company mill at Sylacauga shut down around

1925, two locomotives from there were transferred to Stephenson, also.

Those two Heislers were 85-ton 3 truck Number 7 and 75-ton 3 truck

Number 9. In the late 1920’s, the rod engine, Number 6, had some

work done on it. Buddy Tucker, from the Illinois Central shops at

McComb, came over to Stephenson and put a new crown sheet in Number 6.

He also welded the side rod, and welded the frame. On its first trip

out, she broke the frame again and they cut the engine up for scrap.

The Number 7 then became the regular road engine. It was based at

Stephenson, and would make the trip out to Camp Two to bring in the

log trains at night.

Around 1925 or ’26, Foster Creek Lumber and Manufacturing

Company realized how much damage the skidders were causing to the

younger trees and stopped using the skidders. All logging was done

using mules and oxen after this time. By the late 1920’s, the

logging crews would leave a seed tree on every so many acres of land.

These trees would drop seed on the ground and help regenerate the

forest. These seed trees would frequently be hit by lightning, but

hopefully would scatter seed before dying. The skidders and logging

crews would bury the seed that had fallen the previous years too deep

for it to sprout.

In 1925, construction started on a new logging spur running

south and southwest from Camp Two. Known as the Piney Creek spur, this

line followed Mud Creek and Dry Creek until it reached the Buffalo

River. Just south of Wilkinson, this line eventually crossed the

river, and followed along the south side of the Buffalo River for

several miles. Numerous logging spurs were built off of this line. A

small log camp was built on this line soon after it was built. Known

as the Silver Creek Camp, this camp was located near the Silver Creek

Road. According to Luther Havard, who drove mules for Foster Creek,

this camp had a commissary that was run by Ray Tillery. About 20

families lived at this camp. This camp only lasted about a year.

In 1926, another small camp was built near the juncture of Mud

Creek and Piney Creek. This camp, known as Piney Creek Camp, was

slightly larger than Silver Creek Camp. Camp Two, however, remained

the main camp of the company until the end, and the locomotives were

always kept at Camp Two. Piney Creek Camp was mostly made up of camp

houses for loggers and their families so they would be closer to the

locations being logged. Piney Creek also had a commissary, which at

one time was run by Mr. McLemore. Several dozen portable camp houses

were located here. Approximately 25 or 30 families lived at Piney

Creek at one time. To care for the mules used in the logging, a feed

lot was built near Piney Creek Camp. In the last years of logging, Foster Creek Lumber and Manufacturing was logging south of the Buffalo River near Flat Lake and Ford’s Creek. The railroad at that time was about 27 or 28 miles long. The company would log a section of timber, then lease another section. In the last few months before the mill shut down, logging crews were logging some hardwood timber. They built a spur about six or seven miles into the river swamp. They logged the hardwood out and had the logs piled up about three and four deep all along the spur ready to be loaded when the mill shut down in early 1931. They pulled up the railroad and left those logs in there. Not long afterward, someone built a small groundhog mill there and cut up that hardwood into crossties. When the mill shut down, crews were also clearing the right-of-way and grading a new spur that left the main line near Flat Lake. It ran northward, crossing the Buffalo River, and towards the Hazlit Creek area. They were going to log the steep hills in that area, but the track was never laid.

As with many mills in the South, Foster Creek was severely hit

by the Depression after October 1929. The company was already heavily

mortgaged before that time. Starting in 1930, the mill ran on a

reduced schedule, maybe three or four days a week. The employees’

wages were also cut. The mill managed to struggle on until March 1,

1931, when the mill finally shut down for good. The Whitney National

Bank in New Orleans was forced to foreclose on a mortgage taken out by

Foster Creek on July 1, 1927 for $1,850,000, of which Foster Creek

still owed the bank $890,577.57. The bank sent a representative to

look after the property by the name of Mr. A. J. Gautreau, who moved

his family to Stephenson. Mr. Gautreau looked after the property and

made an inventory of all usable equipment on hand so the bank could

sell it. All of the railroad equipment was brought into Stephenson and

placed in storage.

In March 1932, the bank planned to sell the Foster Creek

holdings. Mr. Young thought that he would be able to buy back the

company for next to nothing. Mr. Wagner and Mr. Curtain, the sales

manager, went to Natchez to see about getting the mill started back

up. Mr. Young went down to New Orleans to work out a deal with the

bank. The bank refused his offer, and the deal fell through, however.

Instead, the property was sold to a non-operating company called the

Foster Creek Lumber Corporation on March 28, 1932 for a total of

$750,000. The Ingram-Day Lumber Company held a mortgage on some of the

timberlands once owned by Foster Creek, and foreclosed on the mortgage

and took possession of those lands. They offered to sell these lands

back to Mr. T. B. McCurley for next to nothing. Ingram-Day also took

possession of the unfinished lumber still at the Foster Creek mill. In

1932, they hired several former Foster Creek employees to finish the

lumber and ship it out. They started up the planing mill to finish the

lumber. After all of the lumber was shipped out, the operation was

shut down for good. The Illinois Central Railroad came in and pulled

up all of the rail on the Foster Creek logging railroads, as they

owned the rail and it was being leased to Foster Creek.

For some time, many people in the Stephenson area were out of

work. After March 1931, the powerhouse at the mill that supplied the

whole town with electricity was shut down, leaving the town without

power. T. B. McCurley was still employed to look after the timber

holdings. His boys rigged up a Model T Ford to run on the logging

railroad. They would go out and inspect the tracks about once a week.

They would inspect the bridges and all of the holdings and make sure

nobody stole anything. If they found something was missing, they would

report it to the sheriff. In the fall and winter, Red, Cletus, and

Leon McCurley would go hunting in the car. They would bring their bird

dogs and guns along when they went out to inspect the property.

Several lumbermen came to Stephenson to look over the Foster Creek

holdings. T. B. McCurley would give them the grand tour of the

property, including the timber holdings. One day, he had spent most of

the day showing the property to Mr. L. O. Crosby, Sr., a prominent

lumberman from Picayune, Mississippi. The two stopped to get a drink

of water from the thermos, when they looked around and discovered that

they were parked on the top of a high hill in the most beautiful

virgin timber around. Mr. Crosby turned to Mr. McCurley and said,

“Well, well, Mr. McCurley, I think you have sold a town and some

pine timber.” Crosby Lumber and Manufacturing Company

L. O. Crosby purchased the former Foster Creek Lumber and

Manufacturing holdings on January 13, 1934. Included in the deal were

the sawmill, railroad equipment, the town of Stephenson, and over

55,000 acres of timberland, estimated to contain about 350 million

feet of virgin Rosemary and shortleaf pine. Lucius Olen Crosby was

born on February 22, 1869, in Lincoln County, Mississippi. After

working in the sawmill business for several years, Crosby began

organizing several sawmills in Mississippi. He operated mills under

various names at Canton, Monroe, Hub, and Baxterville. In 1916 he

joined forces with Lamont Rowlands and formed the Goodyear Yellow Pine

Company at Picayune. The two also purchased the Rosa Lumber Company at

Picayune the following year. Crosby later acquired other mills at

Cybur, Blodgett, and Piave. Later on, his three sons, Robert Howell,

Hollis Hobson, and Lucius Osmond, joined him in the lumber business.

By 1934, only the Goodyear and Rosa mills in Picayune were still

operating. Crosby had a very good relationship with the International

Harvester Co. of Chicago, and through their financial backing was able

to purchase the Foster Creek property. To operate the new property at

Stephenson, the Crosby Lumber and Manufacturing Company was organized

in early 1934. L. O. Crosby served as president of the new company,

while Hollis served as vice president, Howell as treasurer, and L. O.,

Jr. as secretary. Hollis moved to Stephenson to run the new company as

general manager. Hollis had served as plant superintendent of the Rosa

mill in Picayune, and later as vice president of Goodyear Yellow Pine.

On April 4, 1934, the town of Stephenson was officially renamed

Crosby in honor of L. O. Crosby. The town was incorporated again and

T. B. McCurley was appointed mayor of the new town, a position he

served until his retirement in 1950 due to declining health. Crosby soon set out to completely renovate the mill and town. To superintend the mill renovation, they brought in J. R. Clark. Crosby also built several new houses in town. Many people moved to Crosby from Picayune and from the recently closed Virgin Pine Lumber Company at Piave, in Greene County, Mississippi, which cut out in November 1933. Much of the machinery was also moved from the Piave mill to be used at Crosby. The band mills from Piave were brought over to Crosby and used for spare parts. The mill at Piave was an all-electric double band mill with two 9 foot bands, the same as at Crosby. The mill at Piave was built by Filer & Stowell, while the mill at Crosby was a Prescott mill. Many of the electric motors were also brought over from the mill at Piave and used at Crosby. A 6 foot horizontal resaw was brought over from Piave and installed in the mill at Crosby to supplement the 2 band mills and Number One Wickes gang saw that was already in the mill. To get the mill up and running, the Crosby’s also had to replace some of the timbers in the mill that had deteriorated. They also had to level up the carriage trucks and carriage tracks in the mill.

In addition to renovating the mill, Crosby also added a creosote

plant and broom handle plant to the operation at Crosby in 1934. Work on

the creosote plant started in early 1934, and it was placed in operation

in July 1934. It was located east of the mill pond. The broom handle

plant was also added in 1934. Crosby had earlier operated a broom handle

mill in Picayune, where E. L. Robbins worked. He moved up to Crosby to

work in the broom handle plant, where he claimed they made over a

million handles a month for several years. For years a Mr. Smith was

head over the broom handle plant. Those working at the mill knew him as

“Broomhandle” Smith.

When Crosby took over the mill, he inherited all of the

locomotives that were used by Foster Creek. Instead of rebuilding the

logging railroad, however, he chose to convert to logging with trucks.

He brought three Shay locomotives from Piave and Picayune to Crosby to

switch the mill. He still had about a mile and a half of spurs

throughout the mill property, creosote plant, and interchange tracks.

The Foster Creek Heislers sat unused behind the mill for a year or so

before Crosby cut them up for scrap. Crosby did use 65-ton Shay Number 8

to switch the mill for a while. Crosby did sell 45-ton Shay Number Five

to the Graham County Railroad in North Carolina in 1938. The Shays

brought over from Piave and Picayune included 50-ton 2-truck Number 1,

60-ton 3-truck Number 11, and 50-ton 2-truck Number 15. For years,

Number 15 was used at the creosote plant, while Number 11 switched the

mill. Number 1 was used to unload logs at the log pond. Logs were

brought in on trucks and dumped next to logging railroad near the depot.

One of the large Shays would bring a cut of empty log flats and a loader

and crew would load the logs on the cars. The Shay would then set the

cars out on a siding or shove them down to the mill pond. The small Shay

would then spot them two or three at a time for the loader to unload

them and run the logs through the debarker and go on into the mill. For

a short time, Number 1 was used at the creosote plant, but it was deemed

too small to shove the timbers into the retorts.

For several years after purchasing the Foster Creek properties,

Crosby Lumber and Manufacturing continued to add to the timber holdings.

Tracts of timber were purchased as far away as Louisiana and Copiah and

Warren Counties, in Mississippi. Even though Crosby never operated the

Foster Creek logging railroad, a log train was operated over the

Illinois Central occasionally in the 1930’s. A locomotive and crew was

rented from the IC. Crosby’s contract loggers would haul logs to towns

along the IC such as Roxie, Hamburg, and Harriston, where the logs were

loaded on the log cars. Sometimes the train would run as far north as

Vicksburg.

After the mill at Crosby started up in 1934, the mill never did

shut down because of business conditions. One time the mill was forced

to shut down for two or three days because the weather got so cold it

froze the logs. The saws wouldn’t cut through them. During World War

II, many men employed at the Crosby mill quit to join the Armed Forces

or were drafted. Labor was getting difficult to find.

In order to supply the mill with logs, Crosby initiated a program

to manage the land on a sustained yield theory of forest regeneration

and cutting when the mill started in 1934. He hired Jimmy Clark to be

superintendent of logging and forestry. Clark hired a few forestry

people to manage the Crosby timberlands. Crosby hired crews to do the

logging, but hired contractors to deliver the logs to the mill.

After operating for more than 28 years, the decision was finally

made to close Crosby Lumber and Manufacturing Company in 1963. The mill

was finally shut down on November 12, 1963. In 1965, the Crosby Lumber

and Manufacturing timber holdings, totaling more than 152,000 acres,

were sold to the St. Regis Paper Company, who used the tracts of timber

to supply pulpwood for their huge paper mill at Ferguson, Mississippi,

just northeast of Monticello. The mill was sold in 1965 to Hood Lumber

Company, who reopened the mill for a short time. They purchased timber

under lease from St. Regis. Many employees left to find work at other

places, while others chose to retire when the mill closed. The Shay

locomotives used by Crosby were replaced by a Plymouth diesel switcher

in the late 1950’s. The Shays were then stored near the mill for quite

a while. Number One was scrapped at Crosby in 1954, while the others

survived. Number 15 was eventually sold to a railfan in Birmingham,

Thomas Lawson, Jr. Number 11 sat in Crosby for several years before it

was donated to the city of Natchez, where it was placed on display in a

local park in 1965.

|

||

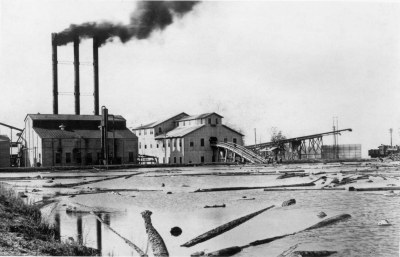

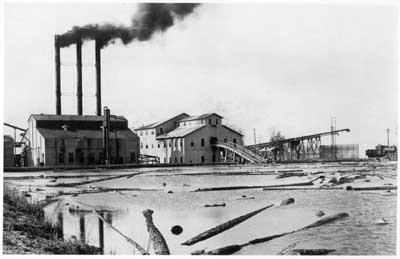

The Foster Creek mill at Stephenson as seen from across the man-made mill pond. |

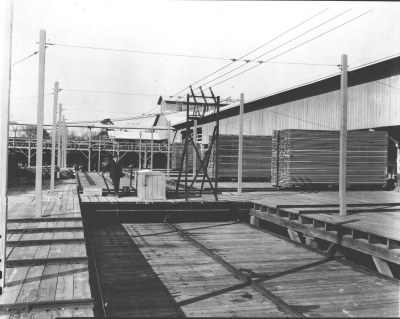

Electric transfer table was located off the green chain coming from the mill. |

|

Cutoff saw at the top of the jack slip. |

Drop sorter used to sort lumber coming from the green chain leaving the mill. |

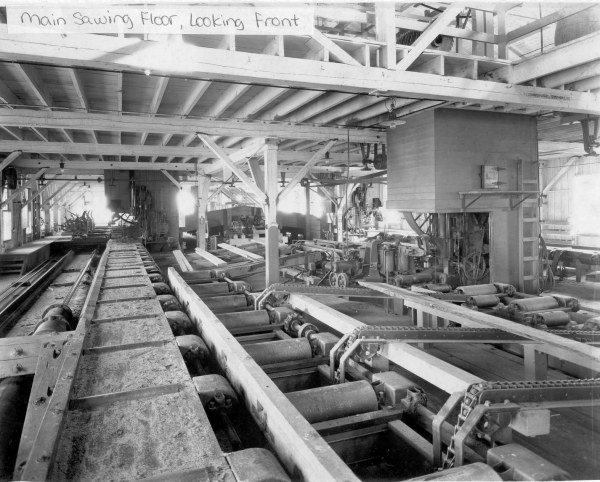

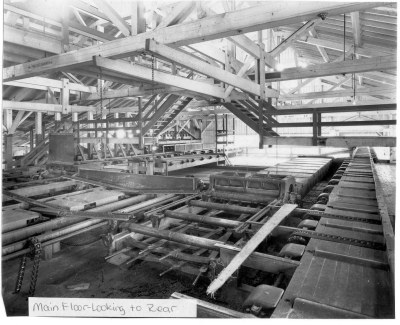

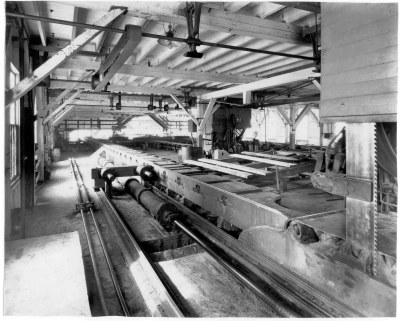

Main sawing deck looking into the mill from the jack slip. Long timbers were cut on the right side, while shorter lumber was cut on the band saw on the left. |

Main sawing floor looking towards the rear of the mill. |

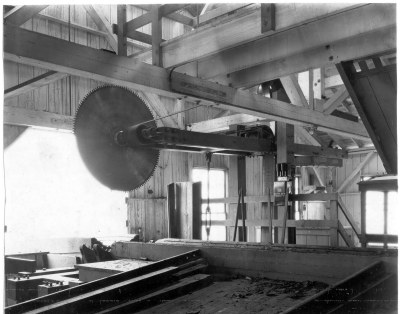

Feed used to move the carriage and the band saw blade at right. |

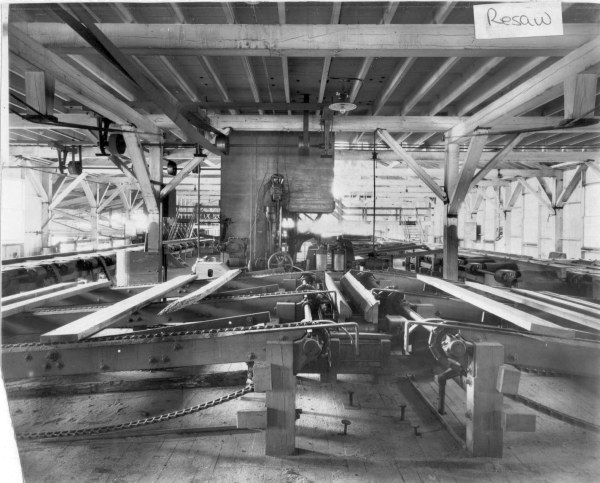

Resaw just to the rear of the main band saws. |

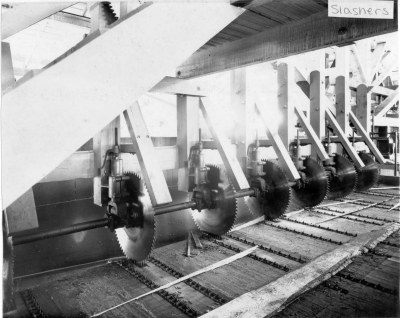

Slashers used to cut waste lumber. |

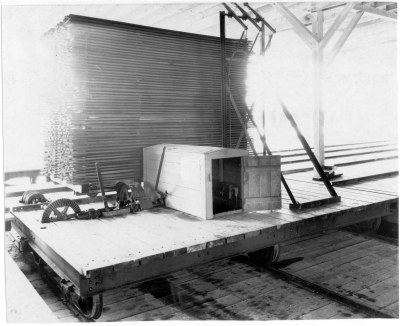

Electric lumber transfer table between the green chain and dry kilns. |

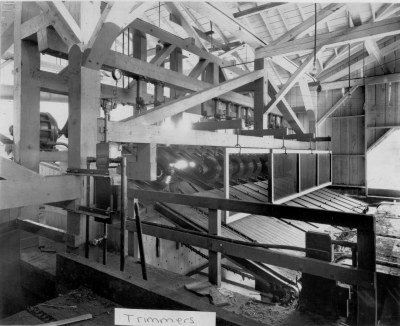

Trimmers used to trim boards to standard lengths. |

Machine shop and coal bin at Camp Two. |

American loader being used to dig mill pond in 1916. |

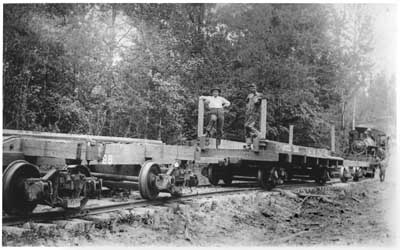

Heisler 3 on the work train with cars of rail used to construct the logging railroad. |

60-ton 2-8-0 Number 6 was bought secondhand by FCL&M in 1916. |

Number 6 tops the steep hill just east of Camp Two with a loaded log train. |

47-ton Heisler No. 3 and crew. |

|

75-ton 3 truck Heisler No. 4 switching loads at Camp Two. |

4-line Clyde skidder dragging logs to a logging spur. |

FCL&M owner Edward Young and a FCL&M engineer with Heisler No. 3. |

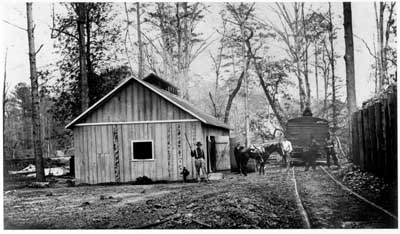

Stables were used to house horses and oxen used in logging operations. |

Log scaler John McCurley at work tallying logs along a logging spur. |

A typical rough logging spur of FCL&M. |

Mules being used to move logs at a bunching site near a log spur. |

Foster Creek office in Stephenson still stands today and is used as the city offices. |

A water car is parked at the Foster Creek portable barn. |

|

Foster Creek Heisler with the tracklaying train. |

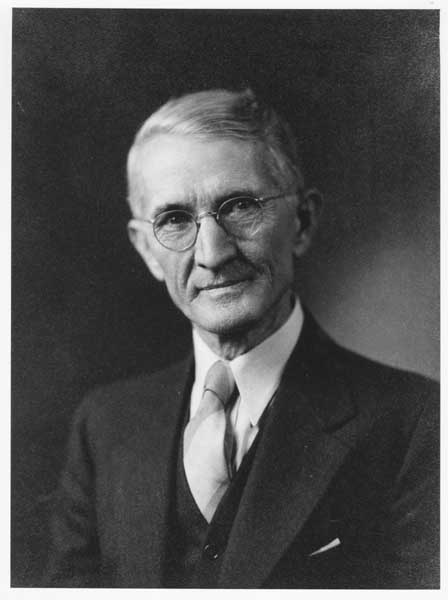

Thomas B. McCurley was responsible for getting Foster Creek Lbr & Mfg to locate in Stephenson, and later served as mayor of Stephenson. |

View at Camp Two looking east with the machine shop and water tank visible on the right. |

|

View looking west showing company houses in Stephenson. |

The water tank at Camp Two. |

|

An unidentified rod engine is backed into a spur just beyond the black quarters at Camp Two while a Heisler is working with the tracklaying train just beyond. |

||

Company officials visit Camp Two. |

Heisler No. 1 weighed 32 tons and was bought secondhand in 1917. |

Heisler No. 4 switches loaded log cars. |

The new Y&MV depot at Stephenson in the 1920's. |

Number 6 at the mill pond. |

Foster Creek Clyde skidder and water car. |

A log spur at a log landing in the early 1920's. |

Another log spur with logs awaiting the loader. |

|

The new commissary at Stephenson. |

||

For more information contact Tony Howe at tonyhowe76@yahoo.com or David S. Price at davidsprice46@gmail.com

All content on Mississippi Rails website is copyrighted by us or the individual or institution noted on the image or accompanying text. Please contact us below for permission to use any image or information contained on this website. Mississippi Rails is not affiliated with any railroad.

©2009 Mississippi Rails